Parainesis in figures

Sectors & Products

Construction / Wood industry

High-quality, durable polyethylene products for builders and manufacturers

Furniture industry

Protective and cushioning packaging solutions for furniture

Food industry

Reliable and safe polyethylene packaging for food products

Automotive

Durable and protective polyethylene products for automotive components

Packaging / Logistics

Innovative and versatile polyethylene packaging solutions for the logistics industry

Paper industry

High-quality and cushioning polyethylene packaging for paper products

Pharmaceutical industry

Safe and reliable polyethylene packaging for pharmaceuticals

Electrical industry

Durable, protective, antistatic polyethylene products for electrical components

Pet food

Animal food packaging

Tisztaszoba

ISO Class 9 szabványnak megfelelő tisztaszobánkban polietilén fóliákat és zsákokat gyártunk olyan iparágak számára, ahol a szennyeződésmentes csomagolás alapelvárás. Levegőszűréssel és a szigorú tisztasági protokoll betartásával biztosítjuk a higiénikus gyártási környezetet.

When you order a polyethylene product, you can pick from a million choices in terms of raw materials, dimensioning, material thickness and formula. Parainesis helps select the optimum solution to make you reach a higher margin, while quality issues disappear.

Get a quoteOur benefits

Quality Assurance

We prioritize high-quality products to meet international standards, giving you confidence in our ability to meet your needs

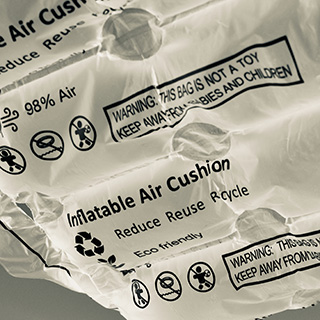

Sustainability

From recycling to renewable energy, we're committed to eco-friendly practices and sustainable solutions for you

Capacity and Scalability

With unmatched industry capacity and scalability, we can meet your diverse needs while maintaining high quality

Technical Expertise

Our deep understanding of polyethylene manufacturing allows us to provide innovative solutions for your evolving needs

Customized solutions

Tailoring our products to your unique requirements, we deliver bespoke solutions that perfectly align with your goals and specifications

Customer Service

93%

of our customers would recommend us

On-time delivery, good quality item. Sells at the most favourable price on the market

Rita E., buyerWhatever question I raised to them, they kindly helped me, they are reliable

N. Nándor, head of warehouse

Environmental awareness in polyethylene production

For a sustainable future and a clean planet for the sake of our children.